I.C.T SS430 selective wave soldering is a high performance equipment developed and assembled in China.

Selective wave soldering is a special form of wave soldering invented to meet the development requirements of through-hole components soldering. It is mainly suitable for the soldering of through-hole components in high-end electronic products.

For example: military electronic products, automotive electronics, switching power supply products and other industries which require higher soldering reliability. I.C.T offline selective wave soldering is a high performance equipment developed and assembled in China. for higher flexibility or multiwave soldering for high-volume processes.product changes without downtime even in multiwave processes, parallel process due to the separation of fluxing, preheating and soldering, operation of up to two spray heads, up to five lower preheatings with optional upper convection heating, perfect for the connection to assembly stands and periphery, connection to traceability systems for process control.

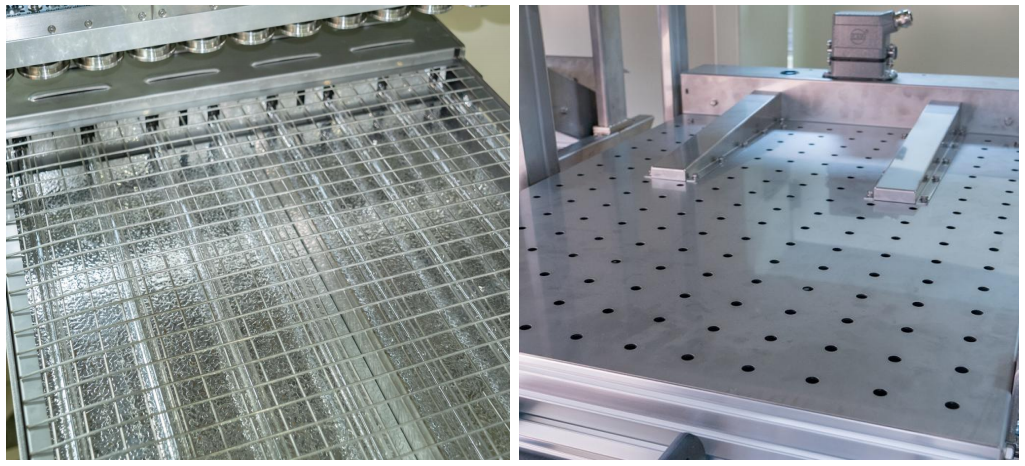

1. Bottom preheating is standard equipped in machine, Position is adjustable.IR heater of Top, Efficient and stable IR heat conduction.

2. Design structure for maximizing preheating area.

3. All round high temperature cotton design to ensure temperature stability.

4. Heat-generating and heat-conducting parts and motors adopt top brands.

5. Maintenance plug-in design. tool-free maintenance mode.

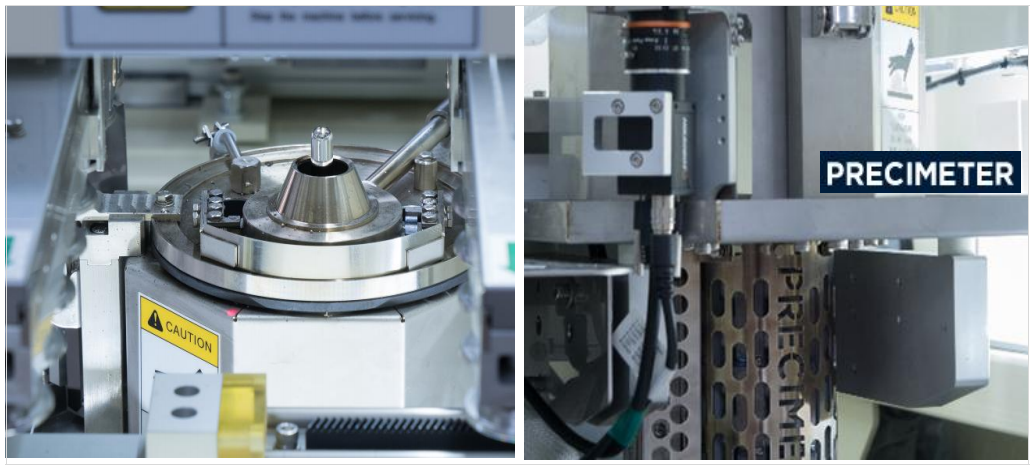

1. Electromagnetic pump coil adopts Sweden “PRECIMETER” brand to ensure the stability and reliability of the peak.

2. Solder temperature, N2 temperature, wave height, wave calibration etc all able to set in software.

3. Solder pot is made of Ti, not leakage. With cast iron heater outside, robust & quick heat up.

4. N2 online heating system, to wet the soldering perfectly and reduce the solder dross.

5. Best tin spraying stability in the industry.

6. Real time visual monitoring and Video can be saved and traced for 900 hours.

7. Visual fast programming to improve programming reliability and efficiency

8. XYZ platform is composed of high precision lightweight sports module and high-speed servo motor.

9. All servo motor are equipped with reducer to ensure stability.

10. Sealed and protected, anti pollution treatment.

11. Omron Magnetic sensor, ensure more accurate movement.

12. Standard with the nozzle automatic cleaning function, Strong cleaning of nozzles with cleaning powder.

13. Cleaning frequency can be adjusted flexibly.

14. Laser detection system for soldering wave height (option).

15. German “SICK” non-contact laser sensor is used to ensure measurement accuracy, no pollution and no error measurement(option).

16. Rational Design of Nozzle Cleaning and Measuring Mechanism

Specifications

| Off-line Selective Wave Soldering Machine |

|

| Model |

I.C.T SS430 |

| Flux Storage Tank |

1L |

| Flux Support |

Flux Alarm, Automatic |

| Spray Nozzle |

Germany Jet Valve (Spot and line spraying) 1set |

| Spray Nozzle Size |

130um (180, 210um Option) |

| Spray Range |

3~8mm |

| Spray speed |

0~20mm/s |

| Spray Nozzle move speed |

0~400mm/s |

| Spray Precision |

0.1mm |

| Spray Pressure |

0.05~0.1 MPa |

| Preheating Mode |

IR Heating |

| Preheating Area |

L500mm*W500mm |

| Soldering Precision |

±0.25 mm |

| Soldering monitoring |

CCD |

| Solder Capacity |

12Kg |

| Max PCB Size |

500*500mm |

| Max PCB Size |

60mm |

| PCB Thickness |

0.5-6.0mm |

| PCB Weight |

<20Kg |

| Operating System |

Windows10 |

| Power Supply |

220VAC±10%, 50/60HZ |

| Dimension |

L1400*W2580*H1722mm |

| Weight |

Approx:700kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.