Low Cost LED Strip SMT Line for Sale

High speed SMD line, LED bulb production line, LED production line, suitable for the production of all LED lights.

❙ Introduce of SMT Production Line Machine

1. Hanwha pick and place machine SM series

| Model | Hanwha SM471 Plus |

Hanwha SM481 Plus |

Hanwha SM482 Plus |

| Spindles |

10 Spindles ×2 Gantry |

10 Spindles ×1 Gantry |

6 Spindles ×1 Gantry |

| Placement Speed |

78,000CPH(Optimum) |

40,000CPH(Optimum) |

30,000CPH(Optimum) |

| Placement Accuracy |

±40μm@μ±3σ |

±40μm@μ±3σ |

±40μm@μ±3σ |

| Applicable Parts |

0402 ~ 14mm(H 12mm) |

0402 ~ 42mm(H 15mm) |

0402 ~ 55mm(H 15mm) |

| Applicable PCB |

Max. 510(L) x 460(W)(Standard) |

Max. 460(L) x 400(W)(Standard) |

Max. 460(L) x 400(W)(Standard) |

| Max. 610(L) x 460(W)(Option) |

Max. 1500(L) x 460(W)(Option |

Max. 1200(L) x 510(W)(Option) |

|

| Dimension(mm) |

1650×1690×1458 |

1650×1680×1530 |

1650×1680×1458 |

2. Full-auto SMT Stencil Printer

| Model | I.C.T-4034 | I.C.T-5134 |

I.C.T-6534 |

I.C.T-6561 |

I.C.T-1200(LED) |

I.C.T-1500(LED) |

| Frame Size(mm) | 470*370 ~ 737*737 |

470*370 ~ 737*737 |

470*370 ~ 850*750 |

470*370 ~ 850*850 |

470*370 ~ 1500*750 |

470*370 ~ 1800*750 |

| PCB Size(mm) | 50*50 ~ 400*340 |

50*50 ~ 510*340 |

50*50 ~ 650*340 |

80*50 ~ 650*610 |

80*50 ~ 1200*350 |

80*50 ~ 1500*350 |

| PCB Thickness |

0.4~6mm |

|||||

| Transport Height |

900±20mm |

|||||

| Support System |

Magnetic Pin/Up-down table adjusted/support block |

|||||

| Clamping System |

Side clamping, vacuum nozzle, Automation retractable Z pressure |

|||||

| Printer Head |

Two independent motorised printhead |

|||||

| Cleaning System |

Dry, Wet, Vacuum |

|||||

| Inspection |

2D Inspection(Standard) |

|||||

| Control Method |

PC Control |

|||||

| Dimension(mm) |

1220*1355*1500 |

1220*1355*1500 |

1330*1530*1500 |

1330*1530*1500 |

2200*1200*1500 |

2500*1220*1500 |

| Weight |

Approx:1250kg |

Approx:1250kg |

Approx:1300kg |

Approx:1300kg |

Approx:1500kg |

Approx:1800kg |

3. Reflow Oven

| Model | L8 | L10 |

| Dimension (L*W*H)mm | 5000x1250x1490 | 5800x1250x1490 |

| Weight | Approx. 1600KG | Approx. 1800KG |

| Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 |

| Length Of Heating Zones | 3121mm | 3891mm |

| Rail Width Adjustment | M(option:A) | |

| Exhaust Volume | 10M3/minx2 Exhausts | |

| Control System | PLC+Computer | |

| Temperature Control Method | PID + SSR | |

| Transmission Agent | Chain + Mesh | |

| Electric Supply Required | 3 phase,380V 50/60Hz | |

| Power For Warm Up | 55KW | 64KW |

| Power Consumption | 8KW | 12KW |

| Warming Time | Approx.25 minute | |

| Temp. Setting Range | Room Temp.-- 300°C | |

| Conveyor Height | 900+/-20mm | |

| Conveyor Speed Range | 300~2000mm/mi | |

| Fixed Rail Side | Front Fixed (Option:Rear Fixed) | |

| Cooling Method | Forced-Air Motor and fan (Standard) |

|

| Model | Lyra 622 | Lyra733 | ||

| Dimension (L*W*H)mm | 5040x1450x1450 | 5800x1450x1450 | ||

| Machine Weight | Approx. 2200KG | Approx. 2400KG | ||

| Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 | ||

| Length Of Heating Zones | 3030mm | 3730mm | ||

| Number of Cooling Zones | 2 | 3 | ||

| Control System | PLC+Computer | PLC+Computer | ||

| Transmission Agent | Chain + Mesh | Chain + Mesh | ||

| Max.Width Of PCB | 460mm | 460mm | ||

| Power For Warm Up | 45kw | 55kw | ||

| Power Consumption | 8kw | 10kw | ||

| Conveyor Height | 900+/-20mm | 900+/-20mm | ||

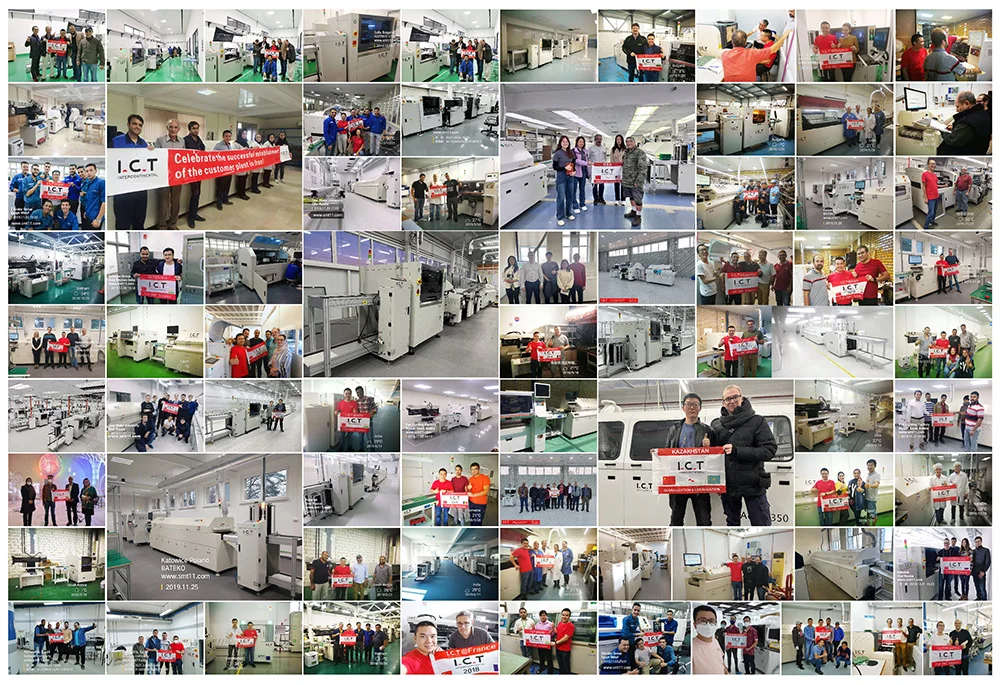

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ I.C.T Global Service

❙ Keywords:

SMT Line, SMT Prodution Line, SMT Assembly Line, SMT Stencil Printer, Solder Paste Printer, Pick and Place Machine, Chip Mounter, SMT Placement, Reflow Oven, SMT Reflow Soldering Oven, PCB Reflow Oven, SMT Loader, PCB Unloader, SMT Conveyor, Wave Soldering Machine, DIP Wave Soldering Equipment, Selective Wave Soldering Machine, PCBA Coating Machine, PCBA Insertion Machine, PCBA Router Machine.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products.

❙ LED Tube Production Line Video