Introduction:

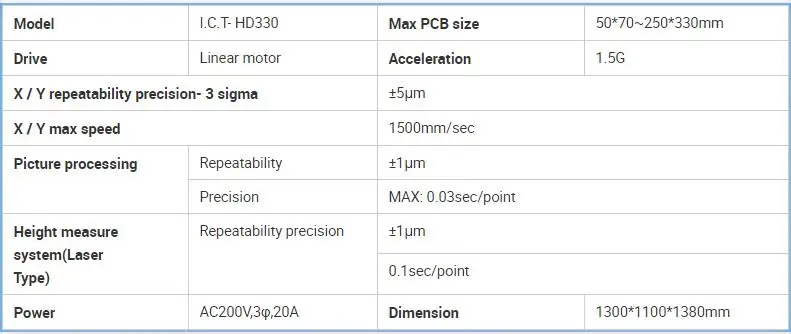

As functionality and performance increase in the electronics field, there is an increasing need for finer and more precise coatings. The HD series machine is a micro-volume, high-speed, high-precision machine that meets the core requirements of artificial intelligence, Internet of Things, CASE, blockchain and other 5G technologies that change life and social fields.

Top advantages:

1. Quickly customize a dedicated platform according to customer needs;

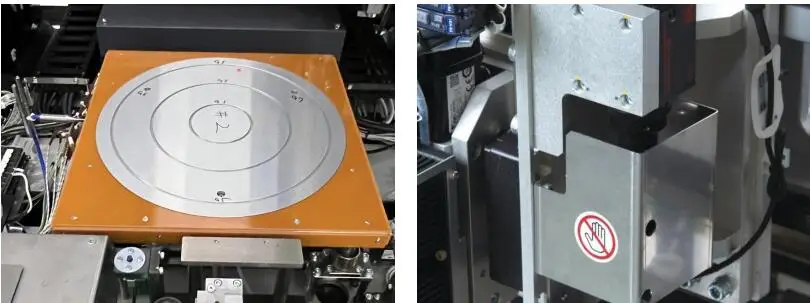

2. By measuring any three points on the PCB, the plane height is calculated, and the needle height is automatically compensated based on the measured height data;

3. Efficient image processing speed reduces visual retrieval and visual inspection time;

4. Non-contact laser can detect 1μm warpage of the substrate;

5. High-speed micro-spraying of high-viscosity materials, automatic correction and compensation of chip cutting and welding errors;

6. Solder paste printing, small amount of high-speed dot spraying, small dot spacing.

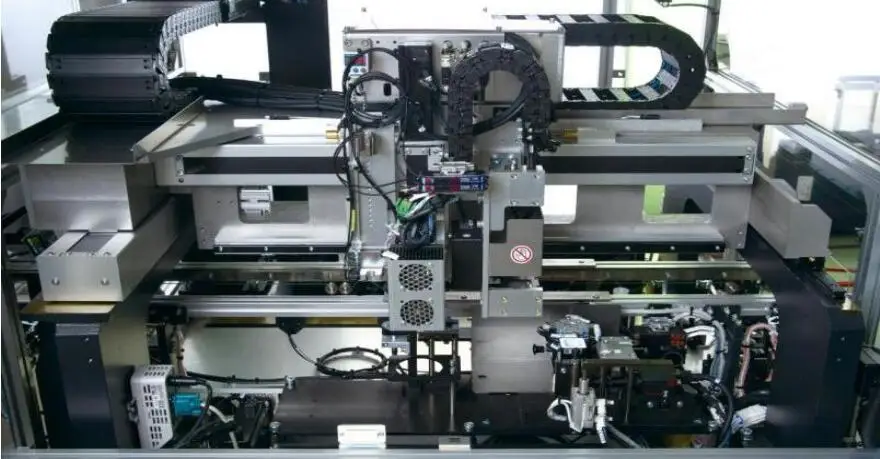

2. Load-type gantry structure ensures the stability and accuracy of the machine during high-speed movement.

1. Customize the exclusive platform to better suit the actual needs of customers;

2. Automatic correction of substrate warp height;

3. Penetration monitoring function, with upper and lower dual cameras, can monitor the material penetration under the flipchip in real time throughout the process, and automatically feedback to adjust the next filling

* Customized mode please contact I.C.T Team.

* I.C.T keeps working on quality and performance,specifications and appearance may be updated without particular notice.

❙ FAQ

Q: What is an Intelligent SMD Component Storage System, and why is it important in electronics manufacturing?

A: An Intelligent SMD Component Storage System is an advanced solution designed to protect and manage Surface Mount Devices (SMDs) in electronics manufacturing.

Q: How does an Intelligent SMD Component Storage System work?

A: This system employs climate control to maintain ideal temperature and humidity for SMD components.

Q: What are the benefits of using an Intelligent SMD Component Storage System for electronics manufacturers?

A: Using this system ensures the integrity of SMD components, reducing the risk of defects and enhancing production quality.

It streamlines inventory management, improves manufacturing efficiency, and provides traceability. This is particularly valuable in industries where precision and consistency are essential, such as aerospace, medical devices, and automotive manufacturing.